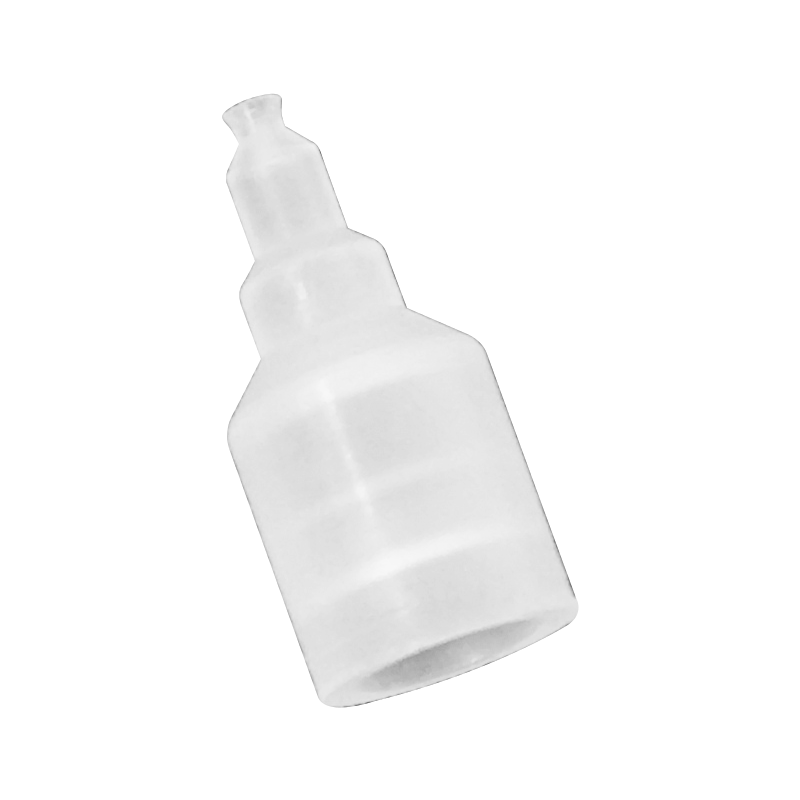

SMC Industrial Pneumatic Rubber Small Nozzle ZPL Series Vacuum Suction Cup Manipulator Accessories Mini Nozzle Suction Cup Silicone Nozzle

ZPL-1.5N

ZPL-1.5S

ZPL-2AN

ZPL-2AS

ZPL-2N

ZPL-2S

ZPL-3N

ZPL-3S

ZPL-4AS

ZPL-4AN

ZPL-4S

ZPL-4N

The mounting parts can be selected according to the application.

Pneumatic components designed and produced to meet the needs of adsorption and handling in the field of industrial automation can be widely used in manufacturing, automated production lines, robotics and logistics.

Product features:

1. Various sizes: There are various sizes such as ZPL1.5, ZPL2, ZPL3, ZPL4, ZPL5, ZPL6, ZPL11, etc., which can meet the adsorption needs of objects of different sizes. Other specifications can be customized if needed.

2. Excellent material: Generally made of high-quality silicone and other materials, it has good flexibility, wear resistance and corrosion resistance, can adapt to different working environments, and can effectively protect the surface of the adsorbed object from being scratched while ensuring the adsorption effect.

3. Strong adsorption force: The design is scientific and reasonable, and it can reach a high vacuum degree in a short time, thereby generating a strong adsorption force. It can stably adsorb light or medium-weight flat objects, such as glass, plastic, metal and wood, etc. It can also be used to clamp or carry fragile items such as film or paper.

4. Easy installation: Equipped with various types of installation connectors, such as ZPL-1.5S-A5, ZPL-1.5N-A5, etc., with different interface forms such as external teeth and internal teeth, which are convenient for connection with various pneumatic equipment and manipulators, and the installation process is simple and fast.

5. Good adaptability: It has good adaptability to the surface conditions of the adsorbed object. Whether it is a smooth surface or a slightly rough surface, it can achieve good adsorption to a certain extent, and can be monitored and alarmed in real time as needed.

Application scenarios

1. Manufacturing: In industries such as automobile manufacturing and electronic equipment manufacturing, it can be used for processes such as handling parts and assembling products, such as adsorbing automobile body panels and handling electronic chips.

2. Automated production line: On the automated assembly line, with the help of manipulators and other equipment, the rapid handling and positioning of materials can be achieved, and the production efficiency and automation level can be improved.

3. Robot technology: As the end effector of the robot, it enables the robot to complete various adsorption and handling tasks, expanding the application range of the robot.

4. Logistics industry: In the logistics warehousing and sorting process, it can be used to absorb and carry cartons, pallets and other goods to achieve rapid loading, unloading and transportation of goods.